|

2578-1626 (Online) Journal Abbreviation: Ceramic Sci. Eng. |

Ceramic Sciences and Engineering (CSE) publishes high-quality articles related to ceramics. The topics related to ceramic sciences and engineering include traditional ceramics (eg. porcelain, glass, etc.) and advanced ceramics (eg. composites, nanomaterials, porous ceramics, mechanical properties and structural design, etc.). Engineering of ceramics such as manufacturing and processing in addition to joining and structural applications are also considered for publication. The journal welcomes submissions on bio-inspired materials designs, and the use of the advanced chemical and physical characterization techniques.

The topics include but are not limited:

|

Online Submissions

Registration and login are required to submit items online and to check the status of current submissions.

Already have a Username/Password for Ceramic Sciences and Engineering?

GO TO LOGIN

Need a Username/Password?

GO TO REGISTRATION

Submission Preparation Checklist

As part of the submission process, authors are required to check off their submission's compliance with all of the following items, and submissions may be returned to authors that do not adhere to these guidelines.

- The submission has not been previously published, nor is it before another journal for consideration (or an explanation has been provided in Comments to the Editor).

- The submission file is in Microsoft Word format.

- Where available, URLs for the references have been provided.

- The text adheres to the stylistic and bibliographic requirements outlined in the Author Guidelines, which is found in About the Journal.

- If submitting to a peer-reviewed section of the journal, the instructions in Ensuring a Blind Review have been followed.

Privacy Statement

EnPress Publisher respects and strives to protect the privacy of its users and visitors. Hence, users and visitors are encouraged to read EnPress Publisher’s privacy policy regarding the usage and handling of user information.

(1) User information

Names and email addresses entered in all EnPress Publisher’s journal sites will be used exclusively for the stated purposes of the journals and will not be made available for any other purpose or to any other party. For submission and peer review, users should register an account for further procedures, including but not limited to name, email, address, interests, affiliation, and postcode, as editors need the information to complete in-house processes (e.g., processing a manuscript).

When users visit the publisher's website, information about the visit is saved in web logs (e.g., device, IP address, time of visit, etc.), which are only used to help improve the structure and content of the website.

(2) User rights

Users have the right to register or update their personal information and contact the publisher to cancel/delete their account if required.

(3) Third-party link

EnPress Publisher is not responsible for private information obtained by third-party websites when users log in via a pop-up screen from third-party software installed on their computer.

When users visit third-party platforms (e.g., LinkedIn, Twitter, COPE, etc.) through hyperlinks from EnPress Publisher’s journal websites, the privacy policy follows the policies of the third-party platforms.

(4) Queries or contact

For any queries about EnPress Publisher’s privacy policy, please contact the editorial office at editorial@enpress-publisher.com.

Article Processing Charges (APCs)

Ceramic Sciences and Engineering is an Open Access Journal under EnPress Publisher. All articles published in Ceramic Sciences and Engineering are accessible electronically from the journal website without commencing any kind of payment. In order to ensure contents are freely available and maintain publishing quality, Article Process Charges (APCs) are applicable to all authors who wish to submit their articles to the journal to cover the cost incurred in processing the manuscripts. Such cost will cover the peer-review, copyediting, typesetting, publishing, content depositing and archiving processes. Those charges are applicable only to authors who have their manuscript successfully accepted after peer-review.

| Journal Title | APCs |

|---|---|

| Ceramic Sciences and Engineering | $800 |

We encourage authors to publish their papers with us and don’t wish the cost of article processing fees to be a barrier especially to authors from the low and lower middle income countries/regions. A range of discounts or waivers are offered to authors who are unable to pay our publication processing fees. Authors can write in to apply for a waiver and requests will be considered on a case-by-case basis.

APC Payment

Payments for APC of this journal can be made through our online PayPal payment gateway. Enter the article no. into the below textbox and select "Pay Now" to proceed with payment.

*Article No. is mandatory for payment and it can be found on the acceptance letter issued by the Editorial Office. Payment without indicating Article No. will result in processing problem and delay in article processing. Please note that payments will be processed in USD. You can make payment through Masters, Visa or UnionPay card.

Vol 6, No 1 (2023)

Table of Contents

Announcements

News: IAC CONGRESS GENEVA 2022 |

|

|

|

| Posted: 2022-08-06 | More... |

News: The Ceramic Road International Ceramic Education Alliance was established |

|

|

|

| Posted: 2022-03-06 | More... |

A new research shows that flexible ceramic nanofibrous sponges with hierarchically entangled graphene networks enable noise absorption |

|

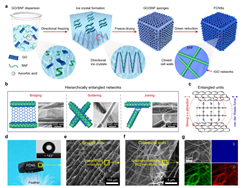

Traffic noise pollution has posed a huge burden to the global economy, ecological environment and human health. However, most present traffic noise reduction materials suffer from a narrow absorbing band, large weight and poor temperature resistance. Recently, researchers demonstrate a facile strategy to create flexible ceramic nanofibrous sponges (FCNSs) with hierarchically entangled graphene networks, which integrate unique hierarchical structures of opened cells, closed-cell walls and entangled networks.

Figure1. Structure design and hierarchical architectures of FCNSs. @Dingding Zong, et al. Nature Communications |

|

| Posted: 2021-11-08 | More... |

| More Announcements... |

ISSN:

ISSN: